Outdoor Electrical Enclosures | Instrument Enclosures | Industrial Enclosures

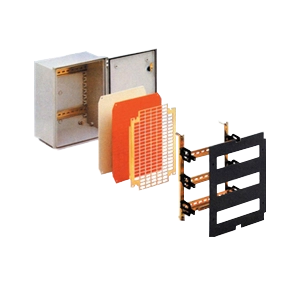

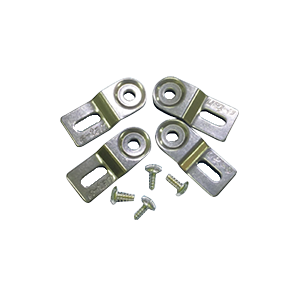

An electrical enclosure is an outer cover or box protecting electrical or electronic equipment and preventing electrical shock. The enclosures are typically composed of two halves which can be opened in case of repairs, battery changes, etc. The two parts of an enclosure are secured together using screws.Even though the electrical enclosures look innocuous, thought and a tremendous amount of work is involved in the design and production. These enclosures protect circuitry and wiring from damage. These enclosures serve not only to keep chemicals, dust, moisture, and other environmental elements from adulterating the electronics but also to protect people from electrical shocks and potential fires. Enclosures must be installed under all applicable local regulations of a place.

What are the best materials for the construction of electronics enclosures?

The most important consideration for the construction of enclosures is the strength and durability of the material used. The basic choice is between stronger and more durable metal and plastic.

Metals

Metals are stronger than most plastics. It is a good conductor of electricity; it blocks incoming and outgoing radio frequency and electromagnetic interference. However, the enclosure needs to be electrically grounded to make it shockproof and prevent short-circuiting. Metal boxes are durable, flame-retardant, and commonly used as fuse boxes and outdoor electrical meters. Generally, metals like aluminum, carbon steel, galvanized steel, and stainless steel are used to make enclosures.

Plastic

Plastic is lighter than metal and less expensive. It is a non-conductor of electricity, and energized wire touching the inside part will not make the enclosure electrically live or a shock hazard. The circuit protection device will not trip due to short-circuiting. Plastic is water-resistant, non-magnetic, flexible, and insulating.

Benefits of Enclosures

The enclosures protect electrical equipment in various facilities- industries, hotels, apartments, etc.

The numerous benefits of the electrical enclosure are as follows-

- Protect circuit breakers and contactors

- Safeguard control panels and switches

- Protect distribution boards and panel boards

- The electronic components are protected from the ingress of dust and water as well as bumps and knocks.

- The electronic components like a fuse, wires, etc., are placed systematically in a specific place.

- The connection of inputs and outputs is easily accessed.

- The use of enclosures allows great visibility of the placement of electronic components due to their shape and color.

- The use of enclosures prevents other electrical faults.